Lathes v mills: Which will be best for your manufacturing job?

Murray Bridge CNC machining firm Kennewell has both – let’s talk about what they can do for you.

This sponsored story is brought to you by Kennewell.

If you need a custom part produced – no matter how intricate or precise – the odds are good that Murray Bridge firm Kennewell can get the job done for you.

“We have world-class precision manufacturing here in Murray Bridge,” director Brett Kennewell says.

“If you want something made, you can get it made here.”

But which machine will be best for your manufacturing job?

This month we look at two of the machines Kennewell use: lathes and mills.

Lathe v mill: What’s the difference?

Both are used in modern CNC machining, in which automated machines produce an object in accordance with preset instructions, with a high degree of precision.

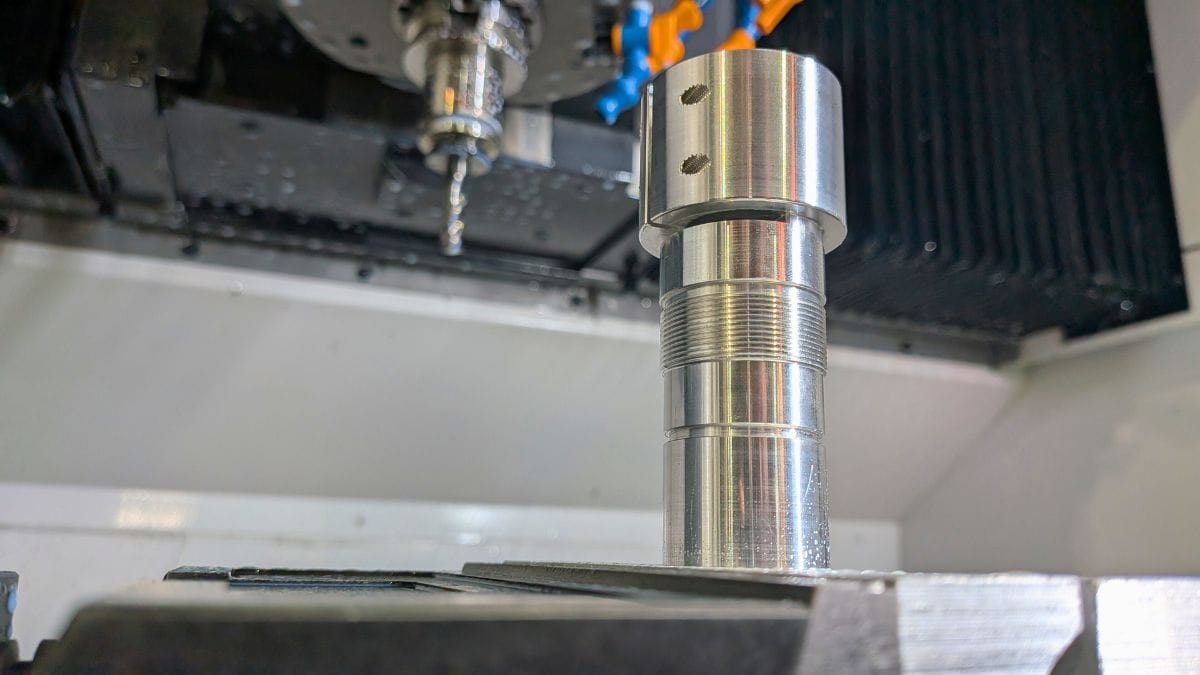

A lathe turns a piece of metal or other material at high speed and works tools along its length to shape it as desired.

“With the evolution of CNC, we’ve added capability to lathes, like live tooling,” Brett says.

“That is, a rotary cutting tool such as a drill can be used to drill holes in a part while it’s still in a lathe … it can be done in one go.

“That reduces the chance of errors.”

A lathe can produce a part up to 360 millimetres in diameter and 600mm long.

Lathe jobs are typically cylindrical: washers, steel tubes, nuts and bolts, stub axles or shafts.

A mill applies rotary cutting tools to a stationary piece of material.

The machines used at Kennewell are capable of applying up to 32 different tools along five axes, allowing for incredible versatility and precision.

“Both the work piece and the tool can be moved during the cutting process, so we can cut pockets, bore holes or machine threads,” Brett says.

The maximum size for a part produced by milling at Kennewell is 1000 by 500 by 300mm.

A milled piece might feature more complex shapes, from a flange to more intricate engine parts, brake calipers or aluminium electronics enclosures.

Kennewell’s mills and lathes can both be automated to reduce labour costs.

The team can feed bars of material into a lathe, to be made into parts and cut off.

Alternatively, they can program a robot to load and unload raw material or prepared work pieces.

What does it all mean for Kennewell’s customers?

Kennewell’s engineering team has the expertise to know which machine will best suit your job.

That’s something that saves the company’s customers time and money in the end.

“We have the ability to manufacture almost any part from almost any material,” Brett says.

“The quantity can vary from one to … the most we’ve ever made of one thing would have been more than 40,000 over a three-year period.”

That order was for a product familiar to most South Australians: water meters, the sort you’ll find in front of your house.

If you’ve bought an agricultural machine from Mannum manufacturer Horwood Bagshaw in recent years, you may well have used something with Kennewell parts in it.

But many of the company’s clients are farmers in search of after-market spare parts, or motor sport or four-wheel-driving enthusiasts with particular needs in mind.

“I’m most excited to explain to people how I can make their parts better and cheaper,” Brett says.

“It’s really fun, getting out and about to small manufacturers in regards to what we can do.

“We still get people who don’t know what we can do, or that we’re here at all.”

Don’t overlook this Murray Bridge firm and its world-class capabilities.

Talk to the Kennewell team today about your manufacturing needs.

- Contact Kennewell: Email quotes@kennewell.com, call 8532 4977 or visit Kennewell at 8 Sturt Reserve Road, Murray Bridge between 8am and 4pm on weekdays.

- More information: kennewell.com.

Advertising to more than 20,000 highly engaged locals can do wonders for your business. Call Jane Intini on 0418 835 768 or email jane@murraybridge.news.