If you can imagine it, Kennewell CNC Machining can manufacture it

The team at this manufacturing firm produces precision parts right here in Australia’s Murraylands, and they want to hear from you.

This sponsored story is brought to you by Kennewell.

If you can imagine it, Kennewell can make it.

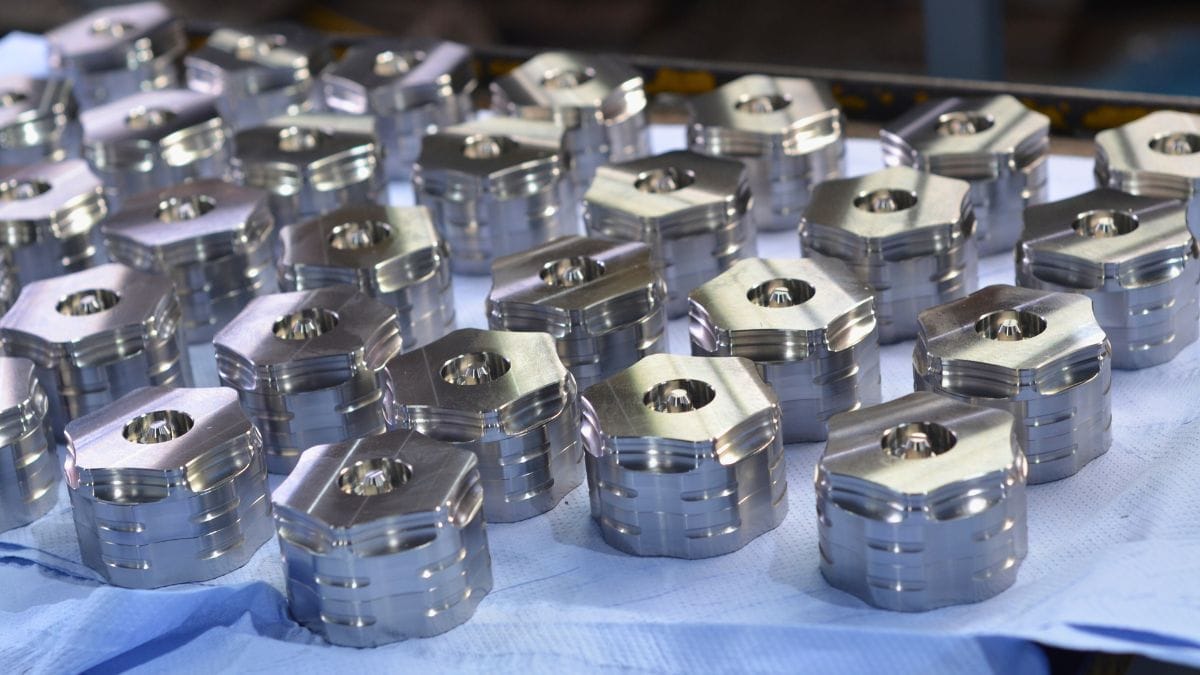

Inside the company’s unassuming Murray Bridge workshop, high-tech robots and machines manufacture anything you might think of, from products for the defence and mining industries right down to herb grinders and four-wheel-drive suspension.

It’s why this CNC machining firm is able to go toe-to-toe with manufacturers around the world, for both quality and price, while remaining one of the best-kept secrets in local business.

And it’s why managing director Brett Kennewell and his team want to hear from you.

If you’ve got an oddly specific problem you need to solve, and can imagine a part or machine that will solve it, Kennewell can manufacture it.

If you need a replacement part for something, but don't know where to source it, Kennewell can mechanically reverse-engineer it and have a new one 3D printed, machined or laser cut.

“We want to find people who have ideas for products, but don’t know how to make them,” Brett says.

“People don’t know what we can do here.

“We can make things here – we can compete with China.”

Rather than one-off jobs, though, Brett encourages you to think bigger.

If you’re willing to pay for a solution to your problem, might others be willing to do the same?

You could be sitting on a lucrative business idea without realising it.

Kennewell can partner with you to make it happen.

“I want to inspire people to have a side business,” Brett says.

“If you have an idea for your hobby, sport, special interest or job, instead of waiting for a part from overseas, make your own.

“Tell us what you need, we can machine it and make it and you can have your own product.”

Precision parts, Australian made

Quality is Kennewell’s north star, whether you’re a new client or need an existing product manufactured to a higher standard.

Brett’s passion for every aspect of the business is evident whenever he speaks.

“You might be getting a product made by a machine shop, but not be happy with the service, or the price, or the timing,” Brett says.

“We can make it look beautiful, straight off the machine.”

Whatever you have in mind, big or small, Kennewell can machine it, 3D print it or laser cut it. Photos: Peri Strathearn.

Kennewell’s services cover every stage of the manufacturing process:

- Design: Translating your drawings or description into a 3D model

- Planning: Considering materials, tools and production schedules

- Prototyping: Testing your design before proceeding to full-scale production

- Manufacturing: With precision

- Milling and turning: Removing excess material to create a specific shape or feature

- Finishing: Hardening, plating, anodising and/or polishing

Their passionate staff travel the world to stay at the forefront of technology and industry knowledge, and foster a culture of creativity, collaboration and enthusiasm.

When they know what you need, they’ll prepare a quote that will tell you how long it will take and how much it will cost.

No matter what they make for you, you will retain any intellectual property.

The company’s success stories are many – they have partnered with the designers of everything from racing car parts to grinders to firefighting aircraft.

Murray Bridge News will share more of those success stories over the coming months, and explore the technology and services they can offer.

But for now: what can Kennewell do for you?

- Contact Kennewell: Email quotes@kennewell.com, call 8532 4977 or visit Kennewell at 8 Sturt Reserve Road, Murray Bridge between 8am and 4pm on weekdays.

- More information: kennewell.com.

Advertising to more than 20,000 highly engaged locals can do wonders for your business. Call Murray Bridge News’ Jane Intini on 0418 835 768 or email jane@murraybridge.news.