How this Murray Bridge shooter turned a niche idea into a $220 product

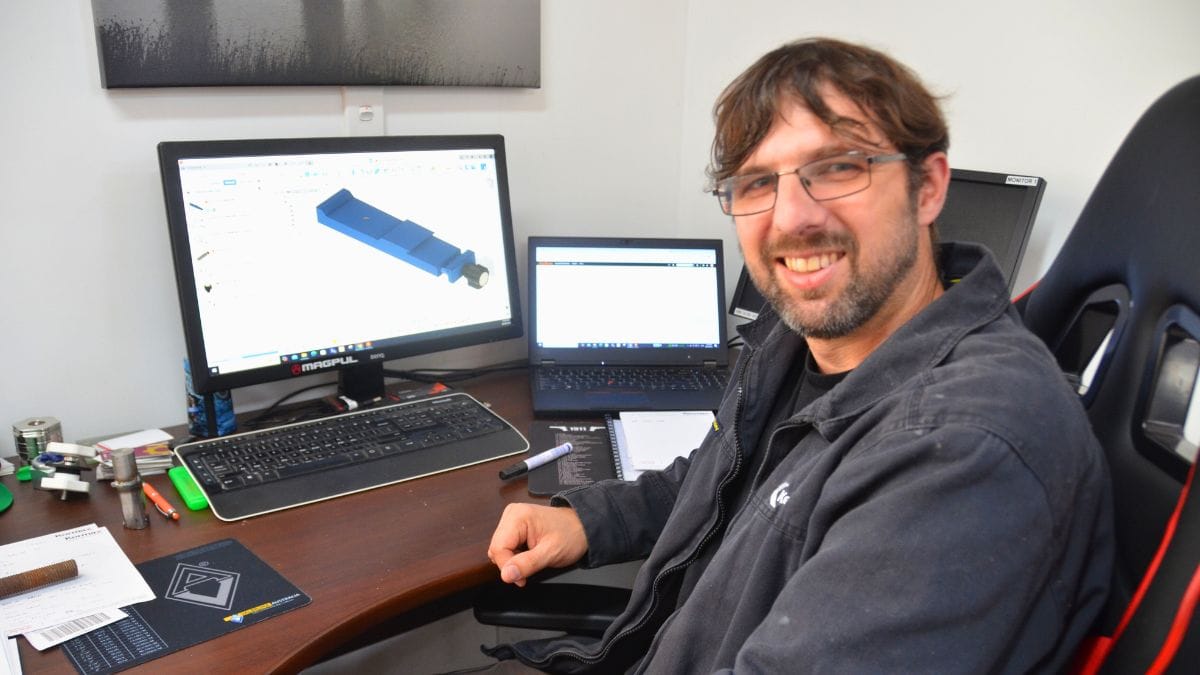

Guy Jackson had a unique problem. Kennewell CNC Machining helped him find a solution – one he is now selling to other rifle enthusiasts.

This sponsored story is brought to you by Kennewell.

Guy Jackson describes himself as “obsessively competitive”.

In his hobby as a rifle shooter, that competitive drive compels him to collect as much data as he can about his performance using a device called a chronograph.

If you were shooting at a rifle range, lying down, you would set it up on a tripod next to your rifle.

But Guy participates in a more mobile version of the sport – and that meant he needed to connect his chronograph to his rifle somehow.

Enter Kennewell CNC Machining.

The Murray Bridge firm has helped him design, prototype and manufacture a mount which enables him to clamp a chronograph to his weapon and collect all the ballistics stats he could ever want while he’s on the move.

Rather than making just one, though, Guy has been able to produce a line of them – and now he sells them for $220 apiece through an online store, Precision Rifle Shop.

What started out as an idle thought has turned into a revenue-generating side hustle.

Kennewell director Brett Kennewell says Guy’s experience has been typical of his company’s clients: someone had a good idea, and needed the expertise to make it a reality.

The Kennewell process

The first step for any inventor or entrepreneur is to have a free consultation with a member of the Kennewell team: sit down and talk about the product you’d like to have made.

Do you just need a prototype, a one-off for yourself, or could you see yourself commissioning a production run and selling your product online?

Kennewell will then be able to give you a quote for the design process.

Next, Kennewell’s engineers will produce a 3D design on a computer: something you can rotate and view from every angle.

That model can be used to produce a 3D-printed prototype or a set of instructions for Kennewell’s production machines.

“We can choose the right type of metal so the customer can … test its function, form and fit,” Brett says.

“Or we can use polycarbonate, nylon, all sorts of high-performance materials.”

Next, you and Kennewell can make any needed alterations to the design, for aesthetic or functional reasons.

If the changes are relatively minor, Kennewell will make them free of charge.

From there, the team will produce more detailed engineering drawings, including all the specifications for your product: materials, tolerances and heat treatment, anodysing or plating, if any of those finishing touches are required.

If you’re not sure how to achieve a certain result, Kennewell’s engineers can help – they have solved all kinds of problems for all kinds of clients before, from agriculture to motor sport.

“Everything is written down to make sure nothing is overlooked,” Brett says.

“We’ll go through the entire process with you.”

If you’re happy, Kennewell can take your project right through to production, whether you want to produce 10 items or 10,000.

Kennewell can bring your product idea to life

Brett and the team take joy in making people’s ideas a reality.

“We get really excited when someone wants to create a product,” he says.

“It’s very satisfying when a product idea comes to life, firstly on a computer screen, then in 3D-printed plastic you can hold in your hand and think about … then in whatever materials you want, finished however you want.”

Guy recommends Kennewell as a partner on any project.

“Brett was very enthusiastic,” he says.

“We took the idea to him, he was interested and engaging and helped along the way, and made suggestions to improve the process and the product.

“Some places, they get annoyed if you want to change stuff, but he was happy to tweak the design until we got it right, and when we went into production, it was completed to a high standard.”

- Contact Kennewell: Email quotes@kennewell.com, call 8532 4977 or visit Kennewell at 8 Sturt Reserve Road, Murray Bridge between 8am and 4pm on weekdays.

- More information: kennewell.com.

Advertising to more than 20,000 highly engaged locals can do wonders for your business. Call Murray Bridge News’ Jane Intini on 0418 835 768 or email jane@murraybridge.news.